We always support partners with our experience

- We perform strength calculations when necessary

- We design and produce project-based fixing accessories

- We develop load-bearing glass structures

If you are looking for the best possible solution, be sure to contact us!

Tension rods

Over 2,000 pieces for R-FIX stainless steel tension rod systems have been installed in Scandinavia, the Baltics and elsewhere. We have valuable experience and reliable technical information in this area. For questions and further information, do not hesitate to contact our specialist!

Tension rods are designed to hang console balconies and canopies, as well as to stiffen steel structures. Our tension rods are characterised by aesthetic appearance, a high degree of safety, and simple installation. All tension rod systems are certified and can be provided with DoP declarations and CE marking.

Show more text

The diameter of the tension rods is between 6 and 36 mm and the tensile load tolerance is between 6.3 and 262 kN. For materials, we use 1.4401 (AISI316) stainless steel with a strong corrosion resistance suitable for the external environment and 1.4301 (AISI304) stainless steel suitable for internal conditions. The advantage of stainless steel tension rods in front of black steel is corrosion resistance, as the hot-dip galvanised black steel tends to get damaged on the threads, and over time corrosion starting the threads becomes visible.

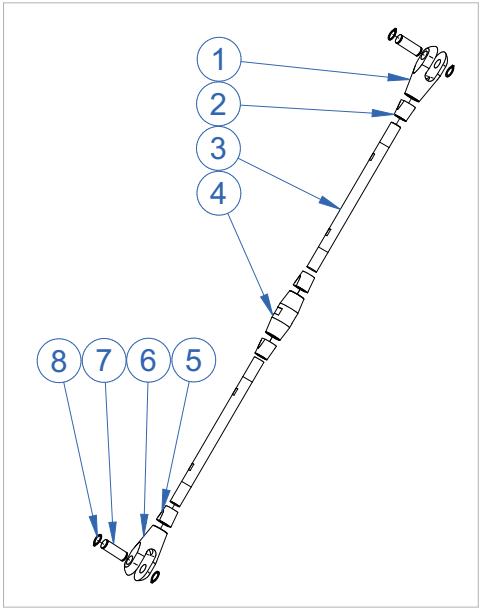

A tension rod system consists of the following elements:

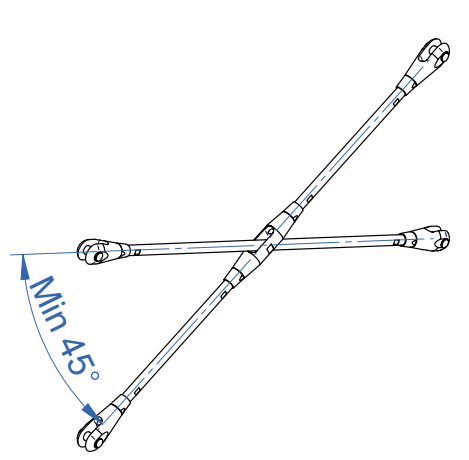

With a single rod it is possible to produce tension rods with a length of 3 to 4 m based on the length of the raw material available. However, by using connectors, it is possible to connect several rods to one another and produce tension rods with a length of 6-12 m. In addition to standard connectors, we offer cross connectors that allow the two tension rods to be attached crosswise.

For installation of tension rods, only standard tools are needed. In order to facilitate installation, the length tolerance of tension rods is +/- 10 mm to +/- 30 mm depending on the diameter of the rod, but using a connector, the length tolerance can be doubled. Upon installation, it is important to ensure that the surfaces of the stainless steel tension rod and hot-dip galvanised anchor plates do not come into direct contact with each other, as this creates chemical corrosion. It would be better to use stainless steel anchor plates, or if this is not possible, the hot-dip galvanised surface must be finished with a durable paint layer.

We keep elements of the tension rod system in stock, and we generally produce rods with a delivery time 2-4 weeks, and in special cases even faster. The R-FIX warehouse is located a 15-minute drive from Tallinn in Kiili, 14 Kurna Street.

Close text