STEP 1

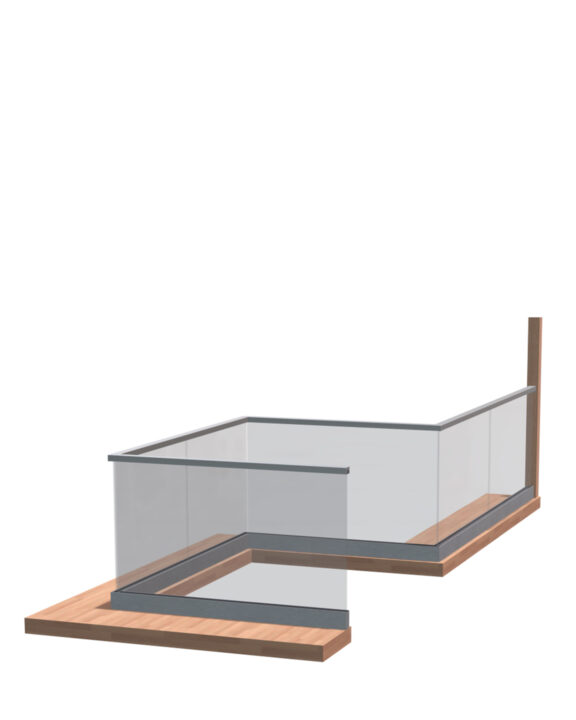

Together with the customer, we map the requirements of the fastening fittings according to the project drawings and requirements. From our side, specialists with extensive experience are involved in finding a solution that is beautiful, safe and competitive at the same time.

STEP 2

We choose suitable standard products or design project-based products. We choose the most cost-effective solutions for the customer. In the design process, we perform strength calculations on the glass and fastening fittings based on the weight of the glass pane and the loads imposed on the glass, such as the operating load and wind load. Based on the complexity of the design, we perform manual calculations as well as FEM calculations with Autodesk Nastran.

STEP 3

We suggest suitable fixing assemblies for the design and provide the customer’s designer with instructions on how to use our products correctly in the design.

STEP 4

We produce the fastening fittings approved for the project and, if necessary, we will carry out load tests in the laboratory to demonstrate their compliance with the requirements.

STEP 5

We deliver the products as agreed, either to the site or to the customer's production facility. We issue the documentation needed for the project with the products – DoP certificates and user manuals.

STEP 6

We will always be there for the customer after the sale, and we will help resolve possible issues.